Plasma is a form of matter in which many of the electrons wander around freely among the nuclei of the atoms. Plasma has been called the fourth state of matter, the other three being solid, liquid and gas.

Normally, the electrons in a solid, liquid, or gaseous sample of matter stay with the same atomic nucleus. In a plasma, a significant number of electrons have such high energy levels that no nucleus can hold them.

An atom that has lost some of its electrons, thereby attaining an electric charge, is an ion. When a gas is subjected to heat or an electric field some of its atoms become ions, and the gas is said to be ionized. An ionized gas, unlike a gas in its normal condition, can conduct electrical current to a limited extent. If the heat or electric field becomes extreme, many of the atoms become ions.

The resulting super-ionized gas is a plasma, which can conduct a large and sustained electric current.

The behavior and properties of plasmas have aroused interest and creative work among scientists and engineers. Applications include electric lamps, lasers, medical devices, energy converters, water purifiers, flat-panel video displays and as well it is used for surface treatment of nearly all kind of materials. About 99% of the visible universe is formed of plasma.

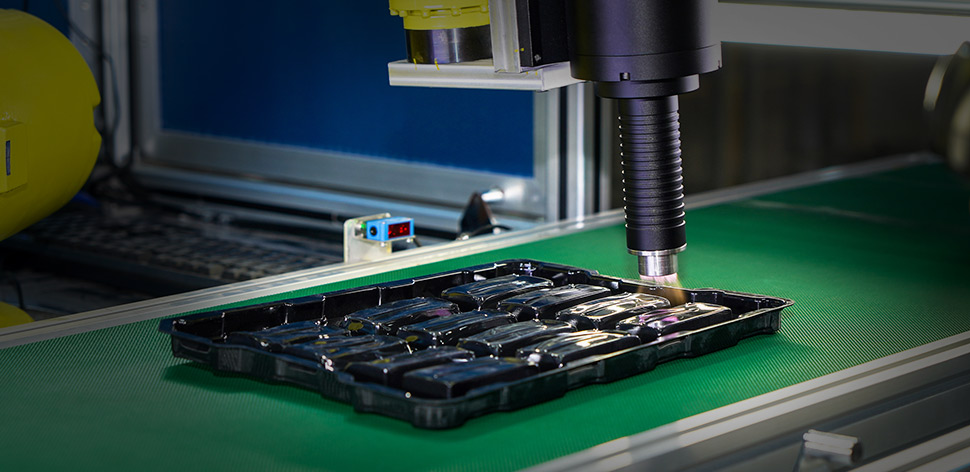

In addition to the technical parameters, we particularly attached great importance to the ease of operation of our systems.All plasma systems can also be easily integrated and controlled into existing production processes without modifications or changes.

Keylink is an innovative and a leading manufacturer in Asia of standard and customized Plasma Systems (incl. Atmospheric & Low-Pressure Plasma) for surface treatment of nearly all materials to enhance adhesion and improve wettability properties.

With our plasma processes, we can replace traditional processes and reduce the CO2 footprint in the production process significantly.

With many years’ experiences in plasma technology, an enthusiasm for innovation and customer-orientation, we develop the technology of our products. We focus on delivering function, reliability, efficiency, and economical solutions for our customers.

In this way we set the trend of modern and environmentally friendly surface cleaning and activation with plasma technology.

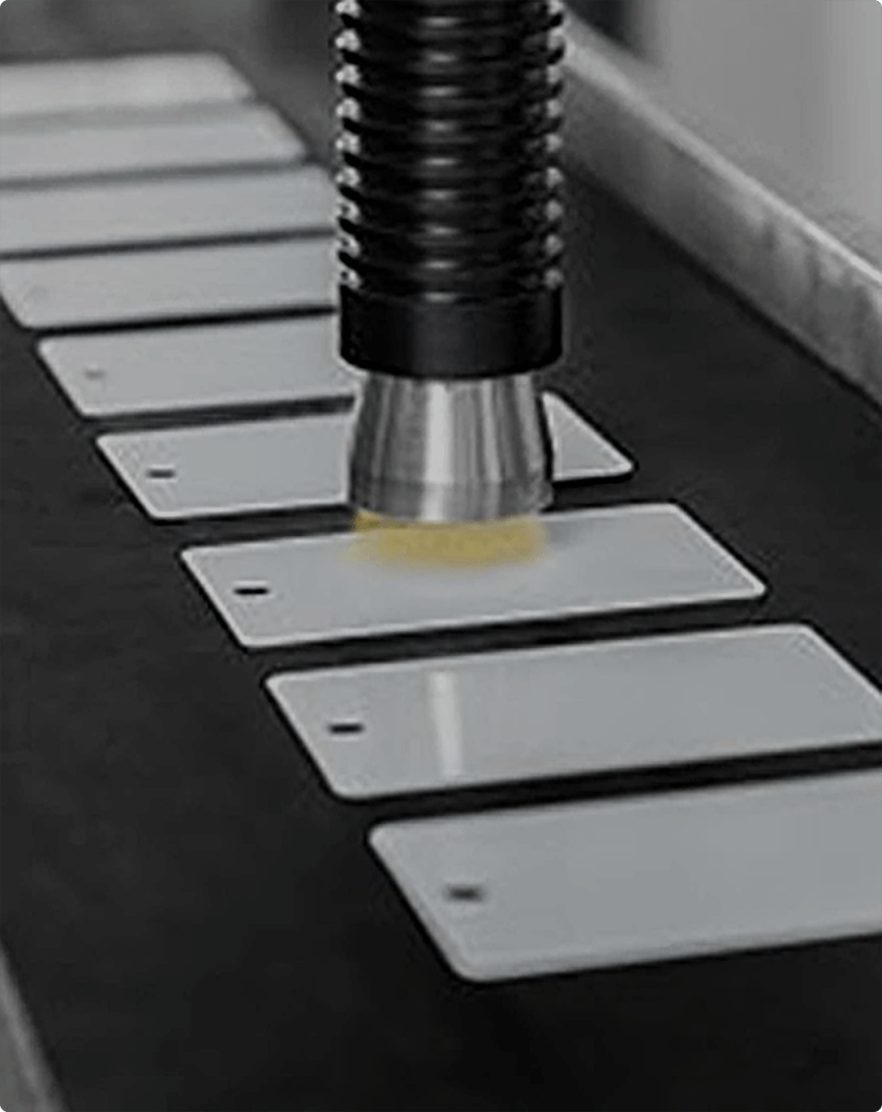

The trend in the packaging industry is adopting smart and sustainable solutions to make product packing more consumer-, brand-, and environmentally friendly. Smart packaging leverages technology will be more and more implemented such as QR codes, smart labels, RFID, and NFC chips

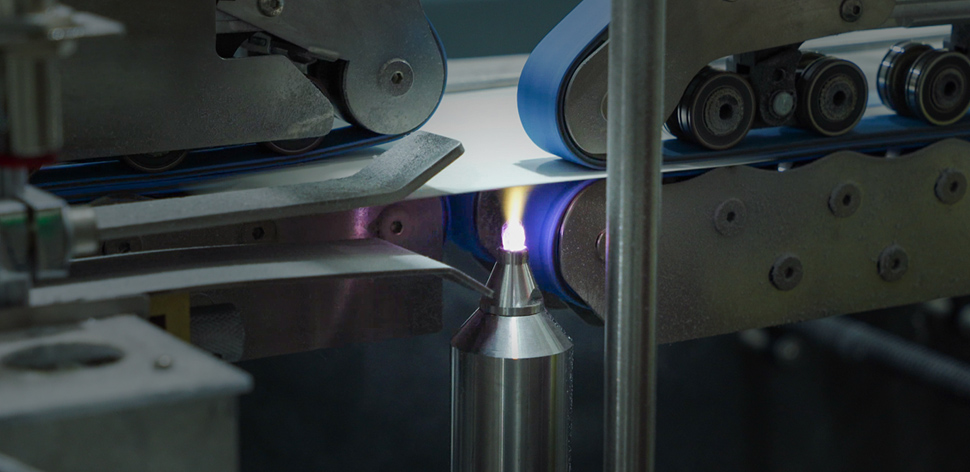

One of the key parameters determining the quality of the print is the adhesion of the ink to the substrate.

aterials with low surface energy such as PE, PVC, PP, PTFE, XLPE< EPDM, Silicone and other materials are difficult to be bonded with inks, sprayed or coated.

Nowadays modern customers have much higher expectations, such as reliable products, proactive service, personalized interactions, and connected experiences across digital channels.

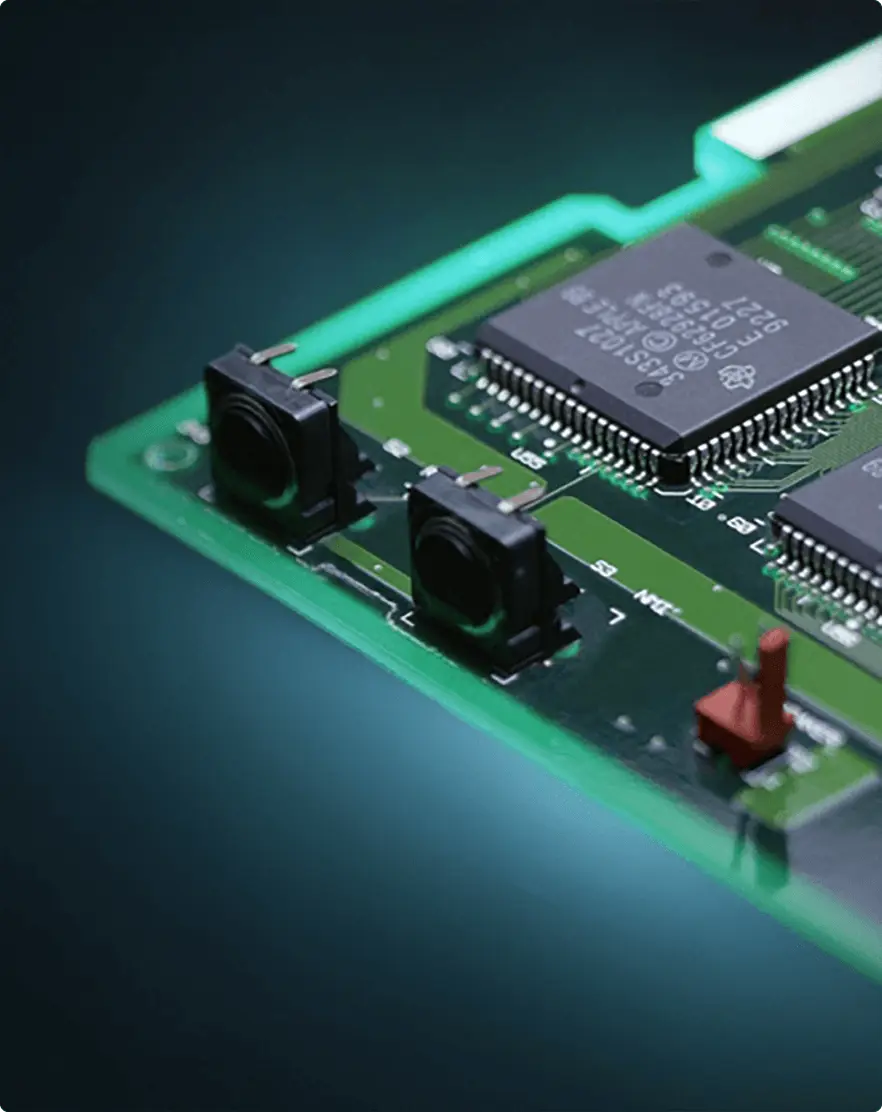

In the electronics industry, plasma pretreatment is a key asset for achieving cost-effectiveness and process reliability.

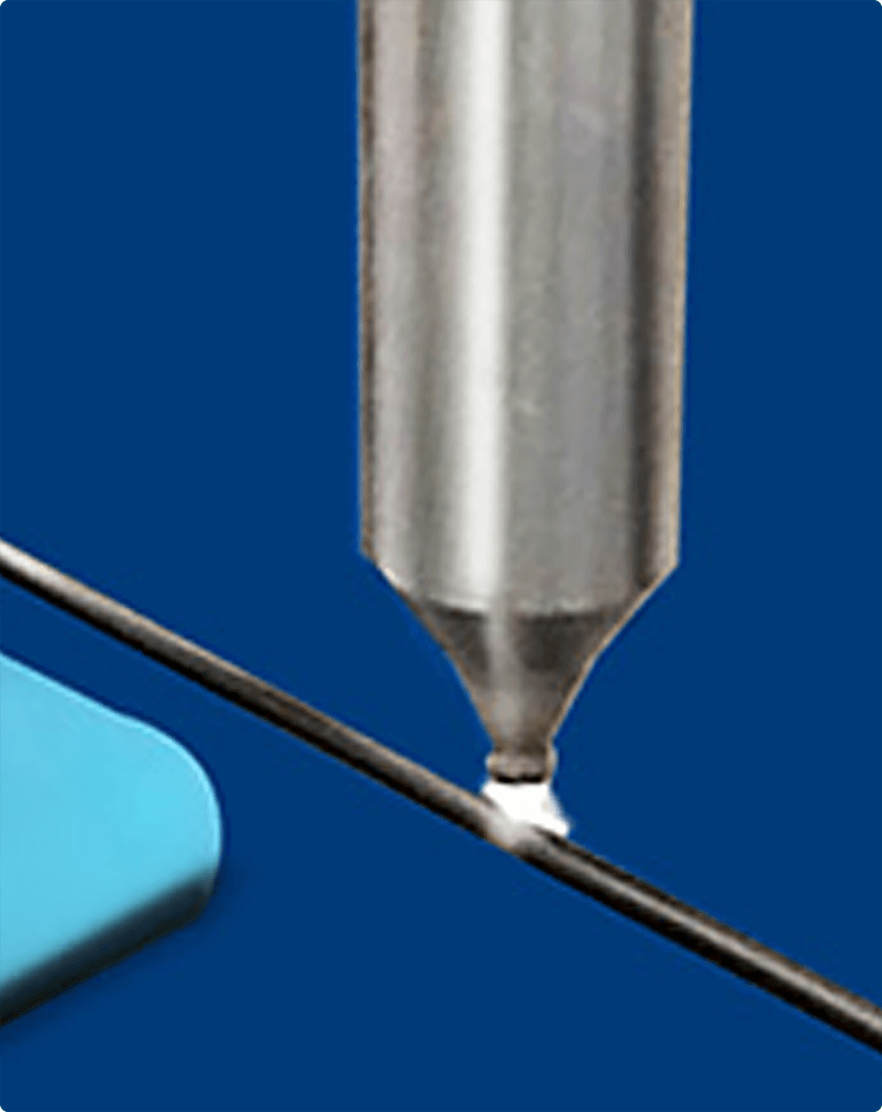

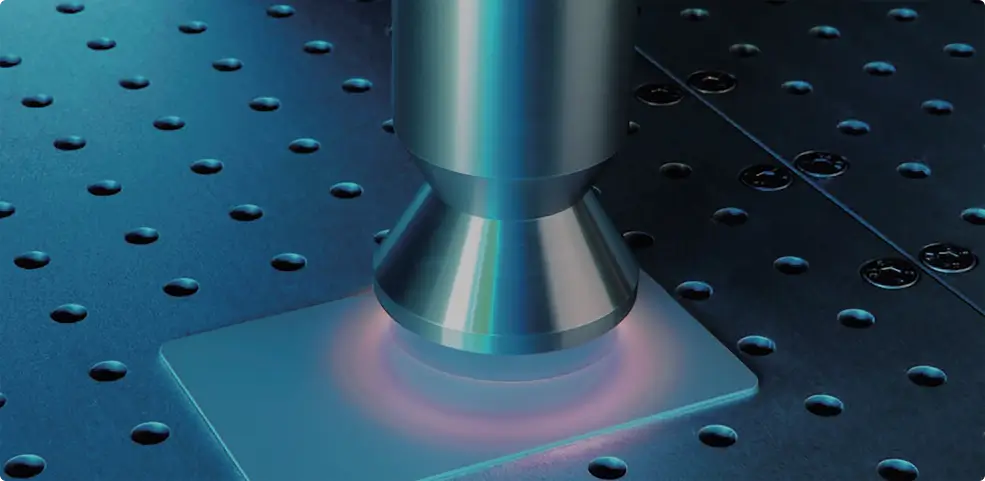

Plasma activation is the process of cleaning and activating a surface as a pre-treatment before applying an adhesive, coating or spraying.

Keylink Plasma Surface Treatment Systems improves its adhesion properties and is an optimal way to improve the strength of the chemical bond between the base material and the adhesive, coating or spraying. The application of the plasma activation process can significantly increase the cross-linking, reliability, and performance of a product.

Improving Bonding

Pre-treatment with Keylink Plasma Surface Treatment Systems increase the adhesion between an adhesive and a base material. It increases the peel and shear in the joint between the adhesive and the base material.

Plasma cleaning technology by using Keylink Plasma Surface Treatment Systems offers solutions for any type of contamination for any substrate. In the cleaning process microscopic contaminations will be removed from a surface by a dry method of turning the foreign particles into a gas. Nearly all materials can be treated. Plastics, metals, rubbers, ceramics or glass are suitable for plasma cleaning. It is an economical, safer, environmentally friendly and more efficient process in comparison to the traditional chemical cleaning method.

Using plasma technology for etching is an optimal treatment removing material from a polymer substrate, metal, oxide, glass or ceramic.There are various advantages to using plasma instead of traditional removal methods, such as chemical etching or mechanical abrasion.With plasma materials can be removed with high accuracy without any damage of the underlying substrate. Beside of this with plasma treatment very thin layers can be removed, the depth of material removal can be controlled precisely.

Booth N5368 Shanghai New International Expo Centre(SNIEC)

ATE Vietnam leads the adhesive industry in sustainabledevelopment, application innovation and technological change,and constantly creates long-term value for the adhesive andsealants industry. The 22th Vietnam Expo In HCM City

Send us a message!

Our system experts are happy to assist you.

Copyright © 2023 Keylink All rights reserved.

Send us a message!

Our system experts are happy to assist you.