The trend in the packaging industry is adopting smart and sustainable solutions to make product packing more consumer-, brand-, and environmentally friendly. Smart packaging leverages technology will be more and more implemented such as QR codes, smart labels, RFID, and NFC chips. Beside of this the packaging industry take on circular packaging solutions using biodegradable and recyclable materials.

Cartons & Paper (printing, gluing, bonding)

Plastic ( plastic containers, caps, closures etc., silkscreen printing, bottle printing plastic container, labelling)

Glass Foil Pouches/Packages ( food packaging, cosmetic container, bottle printing glass, labelling)

The trend in the packaging industry is adopting smart and sustainable solutions to make product packing more consumer-, brand-, and environmentally friendly. Smart packaging leverages technology will be more and more implemented such as QR codes, smart labels, RFID, and NFC chips. Beside of this the packaging industry take on circular packaging solutions using biodegradable and recyclable materials.

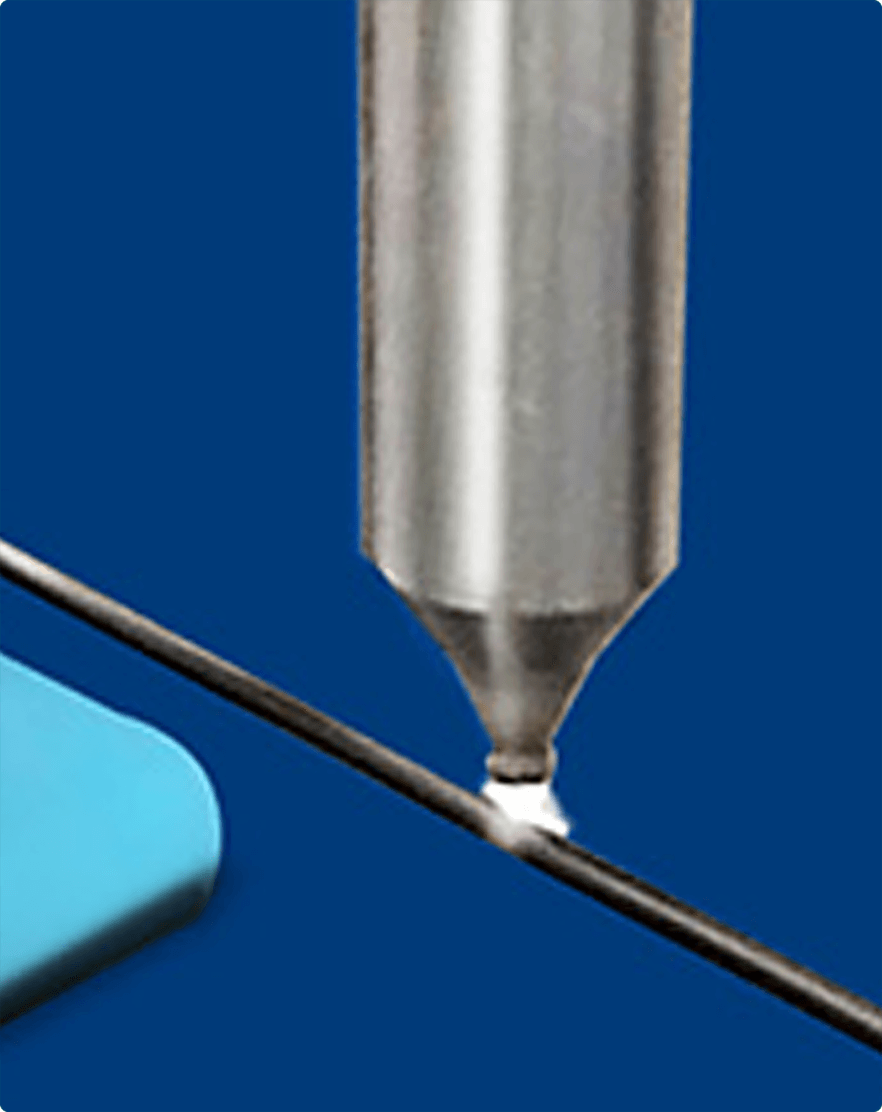

One of the key parameters determining the quality of the print is the adhesion of the ink to the substrate. Without good adhesion, it is impossible to obtain a high-quality print. Pre-treatment for printing using plasma technology improve the surface adhesion significantly, resulting in a high-quality print. Nearly all materials such as metals, ceramics, glass, polymers or textiles can be pre-processed with plasma technology to increase the surface energy and improve the surface adhesion outstandingly.

Materials with low surface energy such as PE, PVC, PP, PTFE, XLPE< EPDM, Silicone and other materials are difficult to be bonded with inks, sprayed or coated. Plasma pre-treatment of base materials to optimize paint or print adhesion is an excellent way of plasma activation. Increasing the adhesion between a material with low surface energy and a paint or print without the use of a primer or adhesion promoters is a significant and an environmentally friendly improvement in the manufacturing strategy.

Nowadays modern customers have much higher expectations, such as reliable products, proactive service, personalized interactions, and connected experiences across digital channels.

Applications using new advanced materials, non-toxic based inks, high-quality prints, sustainable packaging etc. require a pre-treatment based on their low surface energy in the production process, to increase their surface adhesion and wettability, and finally to improve the quality of the finished and/or packed product.

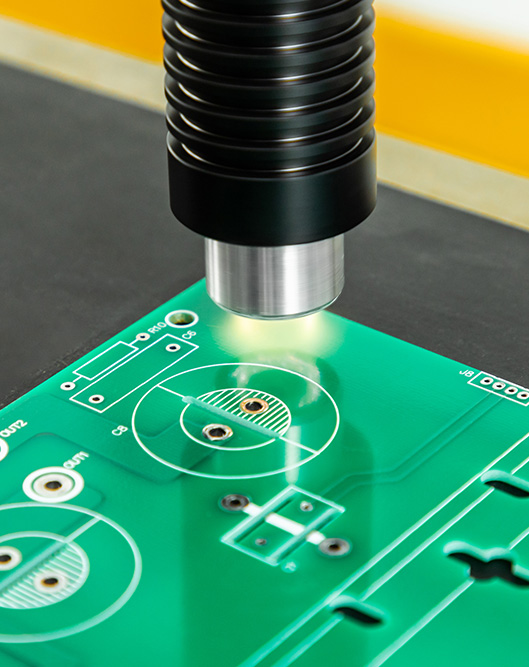

Atmospheric pressure plasma technology is getting more and more important in the automotive industry and proving itself suitable for generating surfaces micro-fine clean for optimal finishing results, creating perfect adhesion, as well as increase the strength of the bond between the base material and the adhesive. From automotive exterior-functional composite materials as well as headlights, windshields to interior parts with complex structures such as dashboards, doors etc., plasma technology is the optimal pre-treatment solution.

Atmospheric pressure plasma technology is getting more and more important in the automotive industry and proving itself suitable for generating surfaces micro-fine clean for optimal finishing results, creating perfect adhesion, as well as increase the strength of the bond between the base material and the adhesive. From automotive exterior-functional composite materials as well as headlights, windshields to interior parts with complex structures such as dashboards, doors etc., plasma technology is the optimal pre-treatment solution.

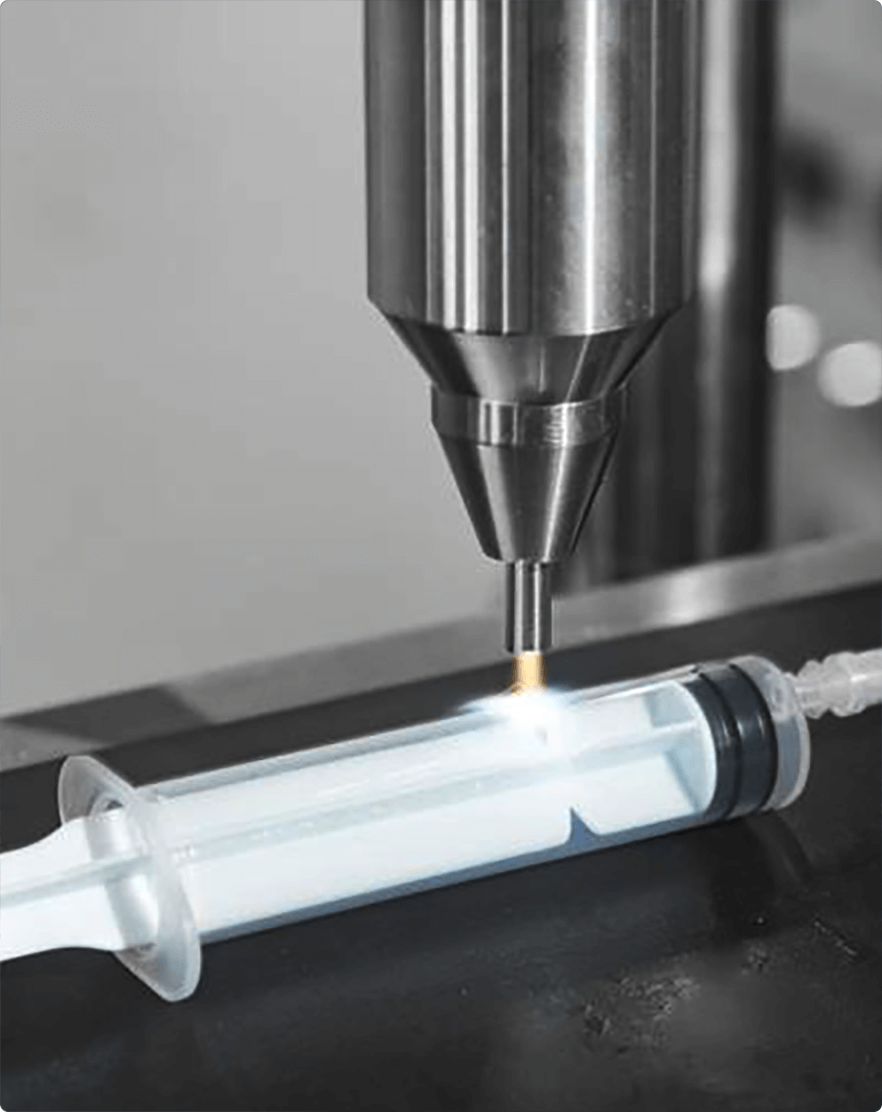

Many devices and equipment used in medical industry require good adhesion to operate properly and ensure accuracy when producing medication, including catheters, hubs, and syringes. Additionally, Plasma Treatment makes intra-ocular lenses hydrophilic, and effectively cleans many medical implants.

Send us a message!

Our system experts are happy to assist you.

Copyright © 2023 Keylink All rights reserved.

Send us a message!

Our system experts are happy to assist you.