Plasma is a form of matter in which many of the electrons wander around freely among the nuclei of the atoms. Plasma has been called the fourth state of matter, the other three being solid, liquid and gas.

Normally, the electrons in a solid, liquid, or gaseous sample of matter stay with the same atomic nucleus. In a plasma, a significant number of electrons have such high energy levels that no nucleus can hold them.

Plasma activation is the process of cleaning and activating a surface as a pre-treatment before applying an adhesive, coating or spraying.

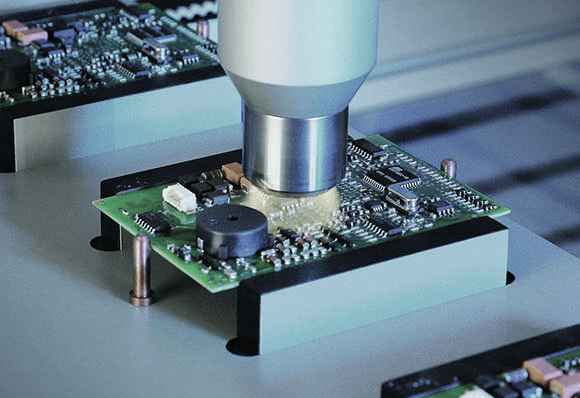

Keylink Plasma Surface Treatment Systems improves its adhesion properties and is an optimal way to improve the strength of the chemical bond between the base material and the adhesive, coating or spraying.

Pre-treatment with Keylink Plasma Surface Treatment Systems increase the adhesion between an adhesive and a base material. It increases the peel and shear in the joint between the adhesive and the base material.

Plasma pre-treatment of base materials to optimize paint adhesion is an excellent way of plasma activation. Increasing the adhesion between a material with low surface energy and a paint without the use of a primer or adhesion promoters is a significant and an environmentally friendly improvement in the manufacturing strategy.

Plasma cleaning technology by using Keylink Plasma Surface Treatment Systems offers solutions for any type of contamination for any substrate. In the cleaning process microscopic contaminations will be removed from a surface by a dry method of turning the foreign particles into a gas. Nearly all materials can be treated. Plastics, metals, rubbers, ceramics or glass are suitable for plasma cleaning. It is an economical, safer, environmentally friendly and more efficient process in comparison to the traditional chemical cleaning method.

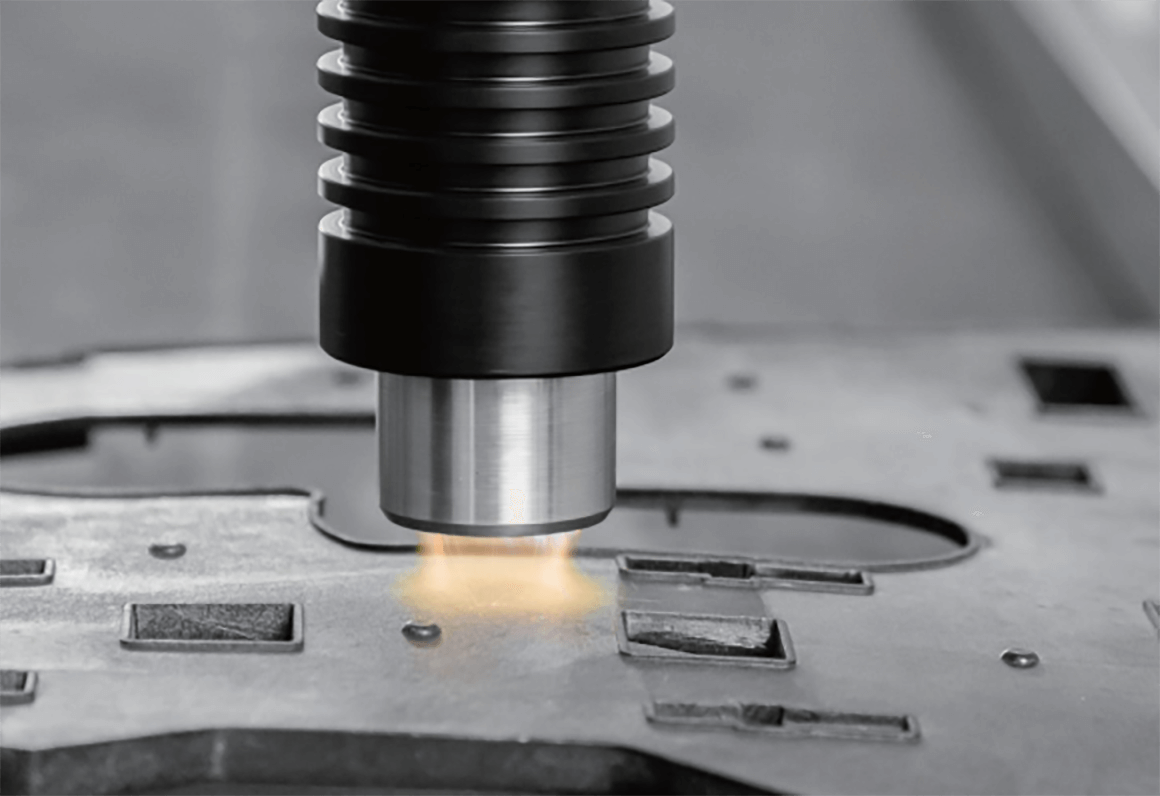

Using plasma technology for etching is an optimal treatment removing material from a polymer substrate, metal, oxide, glass or ceramic.

There are various advantages to using plasma instead of traditional removal methods, such as chemical etching or mechanical abrasion.

With plasma materials can be removed with high accuracy without any damage of the underlying substrate

Many products, parts or components are made of materials such as metals, glass, ceramics etc.,

whose surfaces are very difficult to varnish. Using plasma pre-treatment before varnishing it will clean

and operationalize such materials. As a result, many materials with typical non-stick surfaces can be coated or varnished successfully.

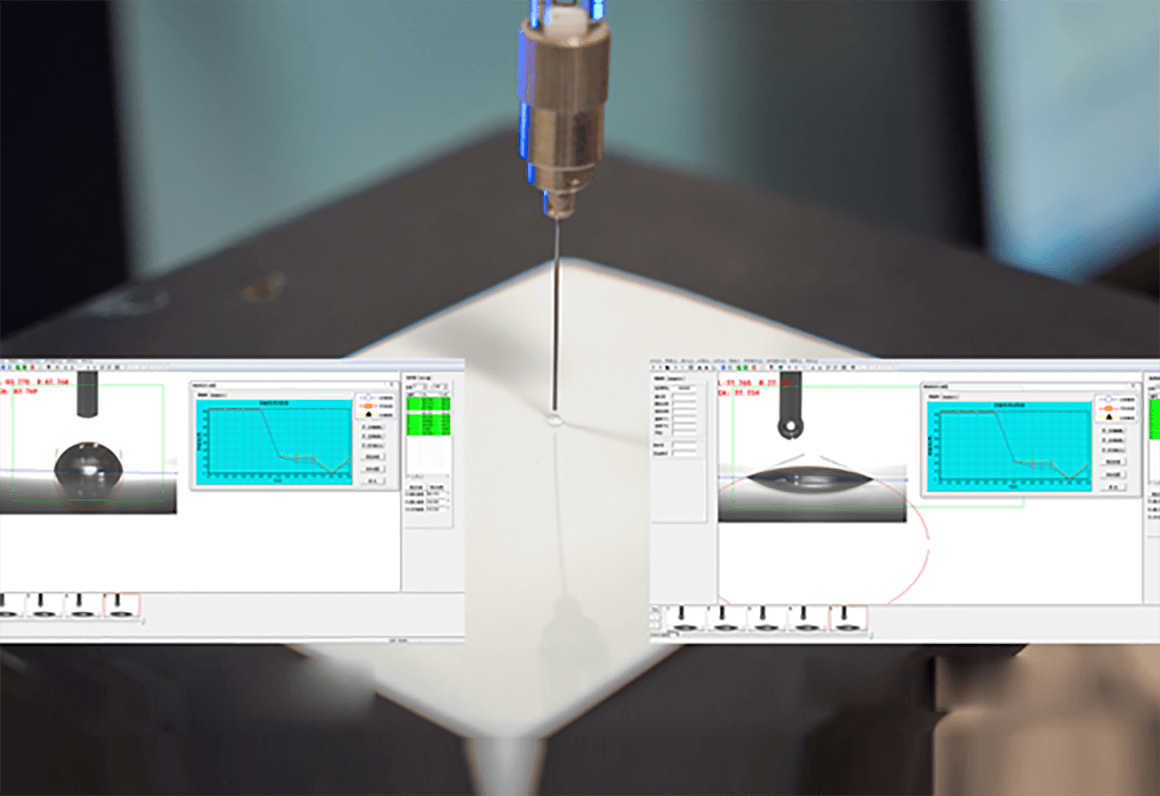

If a substrate has a low surface energy, its wettability is poor and adhesion very scarce, and then needs a surface treatment to increase energy.

Plasma technology as an economical and environmentally friendly treatment offers a wide range of opportunities for improving the wettability.

Plasma cleaning removes all layers of grease, wax or oil without leaving a trace and increase the wettability significantly.

One of the key parameters determining the quality of the print is the adhesion of the ink to the substrate. Without good adhesion, it is impossible to obtain a high-quality print. Pre-treatment for printing using plasma technology improve the surface adhesion significantly, resulting in a high-quality print. Nearly all materials such as metals, ceramics, glass, polymers or textiles can be pre-processed with plasma technology to increase the surface energy and improve the surface adhesion outstandingly.

Send us a message!

Our system experts are happy to assist you.

Copyright © 2023 Keylink All rights reserved.

Send us a message!

Our system experts are happy to assist you.